How Heat Treatment Transforms Ordinary Steel into Powerful Wire

একটা simple প্রশ্ন দিয়ে শুরু করি—

👉 একটা পাতলা Steel wire কীভাবে একটা heavy Spider Camera load নিতে পারে ?পুরো stadium জুড়ে

উড়ে বেড়াতে পারে ?

👉 দেখতে তো একদম ordinary…

👉 কিন্তু behavior? Extra-ordinary.

❓ ছিঁড়ে যায় না কেন?

❓ Stretch হয় না কেন?

❓ এই wire-এর ভেতরে এমন কী আছে?

🔩 What Type of Steel Grade is Used for Such Wire?

- High Carbon Grade?

- Alloy Steel Grade?

- Super Alloy Grade?

এই ধরনের high strength / flexible / wear-resistant wire সাধারণত High Carbon Steel থেকে তৈরি হয়।

✅ Commonly Used Steel Grades

- SAE 1070 / 1080 / 1085 / 1095

- EN 42 / EN 45

- High Carbon Wire Rod (0.70% – 0.95% Carbon)

👉 Why High Carbon Steel?

একটা কথা আগে clear করে নিই—

👉 Carbon is the most powerful alloying element in steel.

Steel-এর character যেটা সবচেয়ে বেশি বদলে দেয়, সেটা হল Carbon।

🔬 Carbon বাড়ালে Steel-এ কী হয়?

Carbon % বাড়ার সাথে সাথে—

- Steel-এর hardness dramatically increase করে

- Strength বাড়ে

- Wear resistance improve হয়

- Microstructure আরও refined হয়

👉 Simple ভাষায় বললে—

Carbon steel-কে “harder & stronger” বানায়।

⚠️ But the Catch — Brittleness

এখন প্রশ্ন আসে—

👉 Carbon বেশি হলে steel তো brittle হয়ে যায়!

তাহলে High Carbon Steel ব্যবহার করি কেন?

Answer টা এখানেই interesting 👇

🧠 Why We STILL Use High Carbon Steel

এই ধরনের heavy loading / high tensile wire-এর জন্য—

👉 Strength is non-negotiable

Low carbon steel দিয়ে—

- Toughness পাওয়া যায় ✔

- But required strength? ❌

High carbon steel ছাড়া—

👉 High tensile strength possible না

💪 What High Carbon Steel Gives Us

Proper heat treatment + drawing করলে High Carbon Steel থেকে পাই—

- ✅ Very high tensile strength

- ✅ Excellent elasticity

- ✅ Superior fatigue resistance

- ✅ Spring-like behavior

- ✅ Long service life under cyclic load

📌 এ কারণেই—

- Spring wire

- Piano wire

- Rope wire

- Tyre bead wire

সবই High Carbon Steel দিয়ে তৈরি।

🔥 The Real Secret — Fine Pearlite Structure

High carbon steel-এর আসল power আসে যখন—

👉 Proper Patenting Heat Treatment করা হয়

🔥 What is Patenting Heat Treatment?

👉 Patenting হলো

একটা special heat treatment process,

যেটা high carbon steel wire-কে

cold drawing-এর জন্য mentally & structurally ready করে।

Simple করে বললে—

Patenting = Steel-এর internal structure train করা

যাতে সে drawing-এর torture সহ্য করতে পারে 😄

❓ Why Patenting Is Needed?

Direct hot rolled wire rod যদি cold drawing-এ পাঠানো হয়—

- ❌ Crack হবে

- ❌ Uneven strength

- ❌ Sudden wire breakage

কারণ—

👉 Hot rolled steel-এর microstructure coarse & unstable

So, drawing-এর আগে

structure refine করা mandatory।

🔬 Patenting Process — Step by Step

1️⃣ Heating

Steel wire rod-কে

👉 850–950°C পর্যন্ত heat করা হয়

এই temperature-এ steel যায়—

👉 Austenite phase-এ(Atoms fully rearranged)

🔬 What does “Atoms fully rearranged” mean?

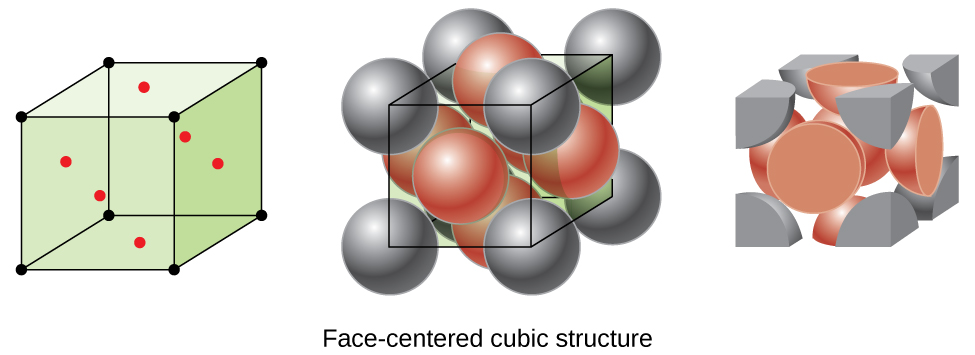

- Iron atoms FCC (Face Centered Cubic) lattice-এ rearrange হয়

- Carbon atoms সহজে interstitial sites-এ dissolve করে

- Structure becomes uniform, soft, and transformable

FCC structure মানে কী?

- Cube-এর 8টা corner-এ Iron atom

- Cube-এর 6টা face-এর center-এ Iron atom

- Carbon atoms থাকে interstitial spaces-এ (gap-এর ভিতর)

📌 কেন এটা গুরুত্বপূর্ণ?

Steel হয় soft, uniform, fully transformable

📌 এই অবস্থাতেই steel ready হয়—

FCC structure-এ Carbon easily dissolve করে Atomic movement easy হয়

- Patenting

- Quenching

- Controlled cooling

- Microstructure engineering

👉 Without Austenite phase, no heat treatment works.

Without FCC Austenite — No heat treatment magic is possible.

🔬 Patenting Process-Step 2

2️⃣ Controlled Cooling (Most Critical Part)

Patenting process-এ এই step-টাই heart of metallurgy ❤️

একটা জিনিস আগে clear করে দিই—

👉 এখানে sudden quenching করা হয় না ❌

(No water quench, no oil quench)

কারণ—

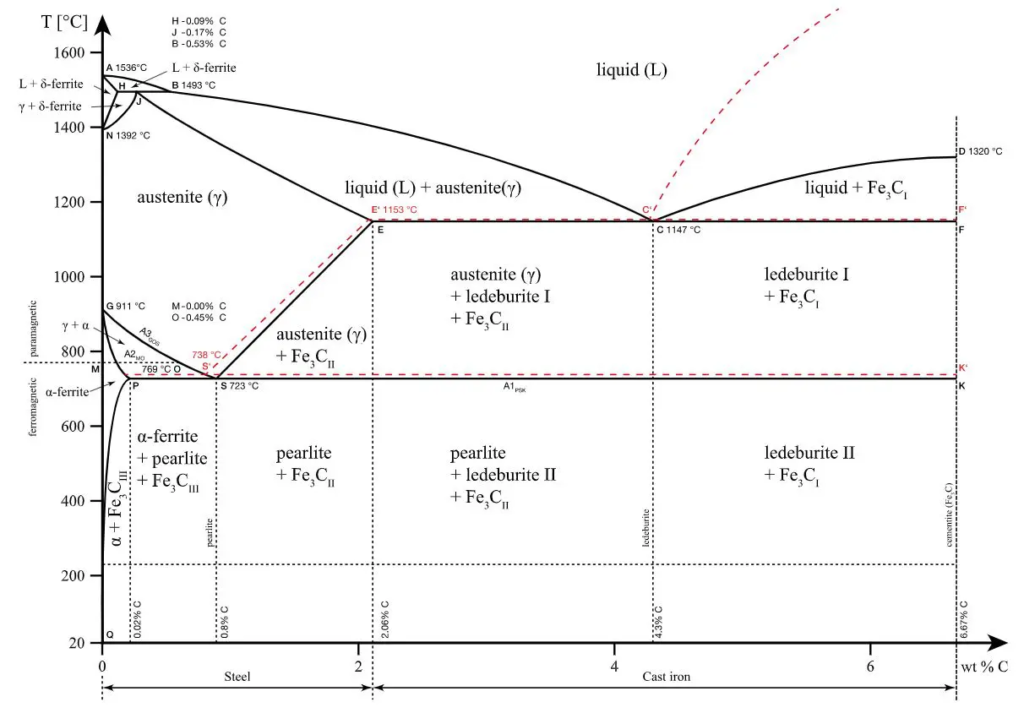

- Sudden cooling → martensite

- Martensite → hard + brittle

- Brittle wire → drawing-এ guaranteed failure

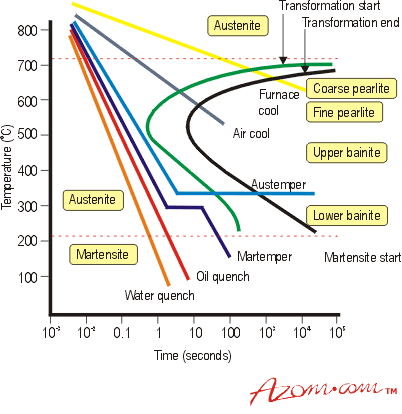

❓ Then What Is Done Instead?

Austenite phase থেকে steel-কে

👉 carefully, intelligently cool করা হয়

Common methods:

✅ Still Air Cooling

- Slow & uniform cooling

- Simple patenting setup

- Moderate fineness of pearlite

✅ Lead Bath Cooling

- Molten lead at controlled temperature

- Very uniform heat extraction

- Extremely fine pearlite achieved

✅ Molten Salt Bath

- Safer alternative to lead

- Precise temperature control

- Industrial consistency

⏱️ Why Cooling Speed Is So Important?

Cooling speed ঠিক করে—

- Pearlite coarse হবে না fine

- Cementite thick হবে না thin

- Crack resistance থাকবে কি না

👉 Too slow cooling → Coarse pearlite ❌

👉 Too fast cooling → Martensite ❌

🎯 Perfect cooling speed = Fine Pearlite

🔬 What Is the Target Structure?

🎯 Very Fine Pearlitic Structure

Meaning:

- Ferrite + Cementite layers extremely thin

- Uniform grain distribution

- High drawability

- High strength potential

📌 এই structure-টাই steel wire-এর জন্য

👉 Golden Structure ✨

Heating makes steel ready,

but cooling decides its destiny.

Patenting-এর Step 2-এ

steel শেখে—

- কিভাবে strong হতে হয়

- কিভাবে bend করতে হয়

- কিভাবে break না হয়ে survive করতে হয়

In patenting, controlled cooling—not quenching—is used to transform austenite into very fine pearlite, which is essential for high-strength, crack-free wire drawing.

Why lead bath gives finer pearlite than air cooling

👉 Because lead bath cools steel at the right speed, uniformly, and without temperature fluctuation.

Steel wire-এর জন্য—

- Martensite too brittle ❌

- Coarse pearlite too weak ❌

👉 Fine pearlite is the only winning structure

And lead bath patenting is the most reliable way to get it.

🧠 What Happens Inside the Steel?

Patenting-এর পর steel-এর ভেতরে তৈরি হয়—

- Extremely fine layers of Ferrite + Cementite

- Uniform grain structure

- Balanced hardness + ductility

📌 This structure is called

👉 Fine Pearlite (Golden structure for wire)

💪 Why Fine Pearlite Is So Powerful?

Fine pearlite মানে—

- ✔ Drawing crack-free হয়

- ✔ High tensile strength develop করা যায়

- ✔ Excellent fatigue resistance

- ✔ Spring-like elasticity possible

👉 Coarse pearlite = weak wire

👉 Fine pearlite = powerful wire

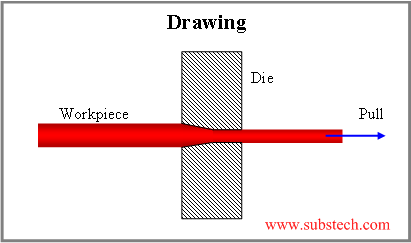

⚙️ After Patenting → Cold Drawing

Patenting শুধু foundation বানায়।

Actual strength আসে—

👉 Cold Drawing / Work Hardening থেকে

- Diameter ↓

- Dislocation ↑

- Strength ↑

Without patenting:

👉 drawing impossible

Patenting is a controlled heat treatment process used for high carbon steel wire to produce a fine pearlitic structure that enables high-strength, crack-free cold drawing.

👉 How Fine Pearlite Converts into Ultra-High Tensile Wire After Drawing

একটা কথা আগে মনে রাখুন—

Patenting strength দেয় না,

Patenting শুধু strength নেওয়ার ক্ষমতা তৈরি করে।

Actual strength আসে

👉 Cold Drawing থেকে।

🔬 Step 1: Fine Pearlite = Perfect Starting Structure

Patenting-এর পর steel-এর ভেতরে থাকে—

- Extremely fine ferrite + cementite layers

- Uniform spacing

- Soft enough to deform

- Strong enough to survive deformation

📌 এই structure না থাকলে—

👉 drawing শুরুই করা যেত না ❌

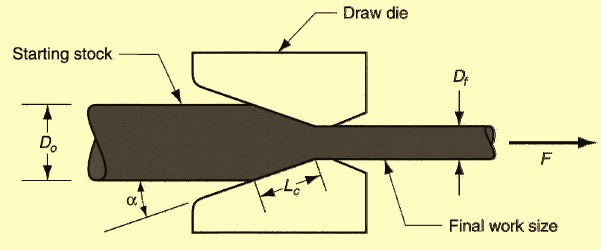

⚙️ Step 2: Cold Drawing Starts (No Heat, Only Force)

Wire কে die দিয়ে টানা হয়—

- Diameter ↓

- Length ↑

- Volume same

🔥 Temperature বাড়ানো হয় না

👉 এটা cold work

🧠 Step 3: What Happens Inside the Steel?

Drawing চলাকালীন steel-এর ভেতরে—

🔹 Pearlite lamellae stretch & align

- Cementite plates elongate

- Structure fiber-like হয়ে যায়

- Load direction-এর সাথে align করে

👉 This alignment massively increases tensile strength

🔹 Dislocation Density Explodes

- Plastic deformation → dislocations multiply

- Dislocations একে অপরকে block করে

📌 Result:

👉 Movement becomes difficult → strength increases

এটাই বলে—

👉 Work Hardening / Strain Hardening

🔹 Step 4: Cementite Becomes Nano-Reinforcement

Fine pearlite-এ—

- Cementite already thin

Drawing-এর পর—

- Cementite breaks into ultra-thin filaments

- Acts like nano-reinforcing rods inside ferrite

👉 Think of it as:

Steel ke andar steel ka reinforcement 💪

📈 Step 5: Strength Skyrockets

Because of—

- Lamellae alignment

- High dislocation density

- Nano-cementite reinforcement

Steel wire-এর strength jump করে—

- From ~900 MPa

- To 1800–3000 MPa (application dependent)

📌 Without fine pearlite:

👉 wire breakage guaranteed

⚠️ But There Is a Limit…

Too much drawing করলে—

- Internal stress ↑

- Ductility ↓

- Sudden failure risk ↑

So industry uses—

👉 Intermediate stress relieving / patenting redraw

To restore balance.

Fine pearlite doesn’t make steel strong by itself.

It allows steel to become strong without breaking.

That’s the real genius.

Fine pearlite provides thin, uniformly spaced cementite layers that deform, align, and fragment during cold drawing, causing intense work hardening and nano-scale reinforcement—resulting in ultra-high tensile steel wire.

👉 What Happens in Intermediate Stress Relieving / Patenting Redraw?

Cold drawing চলতে থাকলে steel wire ধীরে ধীরে—

- Very strong হয় ✔

- কিন্তু একই সাথে

- Over-stressed & brittle হয়ে যায় ❌

এখানেই এই intermediate step দরকার।

🔥 1️⃣ Intermediate Stress Relieving (Low Temperature)

What is done?

Cold drawing-এর কয়েকটা pass-এর পর wire-কে

👉 250–400°C পর্যন্ত heat করা হয়

(Full austenite নয়)

Inside the steel:

- Excess internal stress release হয়

- Dislocation rearrange হয় (partially)

- Brittleness কমে

- Flexibility ফিরে আসে

📌 Important:

👉 Strength পুরোপুরি নষ্ট হয় না

👉 Just enough recovery to continue drawing

⚙️ Why This Step Is Needed?

Without stress relieving:

- Next drawing pass-এ

- ❌ Sudden wire break

- ❌ Die damage

- ❌ Production loss

So this step is like—

Steel-এর short break + physiotherapy 😄

🔥 2️⃣ Patenting Redraw (When Very High Strength Is Needed)

Some ultra-high strength applications-এ

normal stress relieving যথেষ্ট নয়।

Then industry does—

👉 Re-Patenting + Redrawing

What happens here?

- Wire আবার Austenite phase-এ নেওয়া হয়

- Controlled cooling করা হয়

- Fresh fine pearlite structure তৈরি হয়

📌 Meaning:

- Old damaged structure erase

- New drawing-ready structure reset

Then again—

👉 Cold drawing resumes

🔬 Why Patenting Redraw Is So Powerful?

Because it:

- Removes accumulated damage

- Restores uniform microstructure

- Allows more drawing reduction

- Enables even higher tensile strength

Used in:

- Piano wire

- Tyre cord wire

- Bridge cable wire

- Suspension spring wire

🧠 Simple Analogy (Easy to Remember)

- Cold drawing = Gym workout

- Stress relieving = Rest day

- Patenting redraw = Full body reset

Without rest or reset—

👉 Muscle (steel) tears.

Intermediate stress relieving partially removes internal stresses accumulated during cold drawing, while patenting redraw completely resets the microstructure into fresh fine pearlite, enabling further deformation and ultra-high tensile strength without wire failure.

Ultra-high tensile wire strong হয় না

একবারে।

👉 Strength is built in stages

👉 Balance is restored in between

That balance step is—

🔥 Intermediate Stress Relieving / Patenting Redraw